Agridisk

Egypt - Alexandria

Food processing equipment manufacturers & Technological Innovations

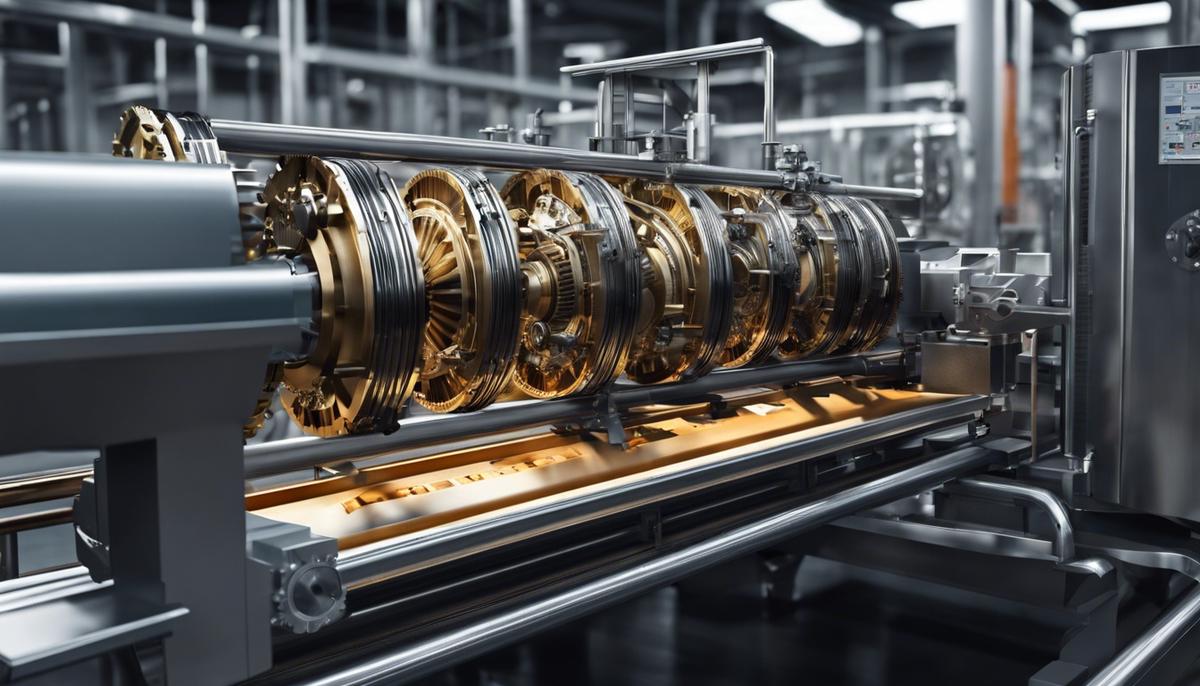

Description: In an era defined by relentless advancement and global interconnectivity, the food processing equipment manufacturing sector is no exception to the multifarious influences of technology, market dynamics, competition, and environmental consciousness. The industry is witnessing a rapid integration of avant-garde technologies and intellection, from automation and artificial intelligence to data science. This wave of technological evolution is revolutionizing production procedures, enhancing efficiency, and offering cutting-edge solutions to the diversifying needs of the industry. Coupled with this, the market shifts, led by the dynamics of consumer demand and ongoing regulative modifications, call for an in-depth understanding of the global trends and forecasts shaping the industry's future. Innovations within the food processing equipment manufacturing industry have been surging at accelerated rates, driven by the integration of groundbreaking technologies. Opportunities for the skillful entrepreneur are inherently vast. Among the game-changers cutting a groundbreaking path are the advancements in Automation and Robotics, as well as the Internet of Things (IoT). These evolving technologies are shaping the industry landscape with their ability to deliver high efficiency, consistency, and accuracy in production, crucial in catering to the growing, consumption-driven global populace. Automation and Robotics, the frontrunners of productivity and consistency, are revolutionizing the food processing equipment industry. By delegating repetitive, time-consuming tasks to machines and robots, manufacturers are significantly reducing the possibility of human error and contamination. This doesn't just enhance production efficiency; it safeguards the integrity of the final product – pivotal in an industry where consistency and hygiene are paramount. In harmony with automation, the Internet of Things is providing a degree of control and predictability previously deemed elusive. IoT technology empowers businesses to monitor, in real-time, the most intricate details of their operation, from analyzing machine performance to overseeing inventory management. This unprecedented connectivity between devices contributes not only to the improvement in operational efficiency but also enables speedy resolution of potential issues – a prerequisite for consistent high-level performance in a rapidly moving business environment. A dynamic approach to these technologies is necessary for those keen on thriving in this evolving landscape. To embrace automation, robotics, and IoT in the food processing equipment manufacturing industry isn't just about staying relevant amid the lightning-fast progress of technology. It's about leveraging these innovations to catalyze growth, shape the industry's future, and deliver superior value to consumers. Diving right in, one dominant trend permeating the surface of the food processing equipment manufacturing industry is sustainability. With increasing environmental awareness globally, consumers are demanding greener practices, pressuring manufacturers to reduce their carbon footprints, conserve water, and limit waste. This demand has buoyed the development of energy-efficient and waste-minimizing machinery. Examples include but are not limited to, machines with conservational water usage, automated waste management systems, and usage of renewable resources for producing equipment. Businesses that adopt such sustainable practices not only meet environmental regulations and consumer demands, but also witness substantial cost savings, resulting in a palpable impact on the bottom line. Another significant trajectory is the adoption of Nanotechnology – an exciting frontier that promises to restructure the landscape of food processing equipment manufacturing. Nanotech applications range from boosting food safety by detecting contaminants to improving the nutritional value of food. By incorporating smart nanoparticles into processing equipment, manufacturers can ensure a prominent increase in sanitary conditions and prevent pathogenic contamination, which is a paramount concern in the industry. Looking forward, a blend of emerging technologies and an attuned awareness towards sustainable practices are predicted to shape the future of the food processing equipment manufacturing industry. It is imperative for companies to keenly observe these trends, adjust their sails accordingly, and seize the prevailing opportunities for both growth and creating value for consumers. This persuasive entrepreneurial adaptation and innovation are key to capitalizing on the dynamic and ever-evolving market needs. A close and discerning look at the food processing equipment manufacturing industry reveals a textured landscape of competitive giants and nimble upstarts. The most dominant players in this robust sector include companies such as GEA Group, Buhler AG, Marel, Tetra Pak, and Alfa Laval. These corporations have achieved their market positions by incorporating strategic practices such as product innovation, mergers and acquisitions, and partnerships with other industries, thereby expanding the depth of their offerings. GEA Group, for instance, keeps a competitive edge with its comprehensive product portfolio, offering everything from slicing and packaging machines to fully automated production lines. Meanwhile, Tetra Pak's innovative packaging solutions have become ubiquitous worldwide, emblematic of the company's commitment to sustainability. This commitment is clear, as the brand continually invests in developing packages from renewable resources, thus synergizing their operations with the rising demand for eco-friendly practices. Another interesting entrant in this industry is Buhler AG. Known for their relentless pursuit of technological finesse, they've incorporated nanotechnology into their processing equipment. This leap has not only bolstered the safety measures in their processing facilities but also significantly enhanced the nutritional integrity of the food processed using their equipment. This forward-thinking approach positions them well within the market, poised to capture a burgeoning consumer base increasingly focused on health and wellness. Companies in the food processing equipment manufacturing industry must continually adapt and innovate to sustain market relevance. Meticulous observation of industrial trends and strategic adaptations are the price of competitiveness in this ever-evolving ecosystem. Businesses that can leverage technological advancements, demonstrate an unwavering commitment to sustainability, and continually deliver value to consumers will find the greatest success within this high-demand industry. As the market economy evolves, sustainability in the food processing equipment manufacturing sector has emerged as a pivotal element. Flexible, forward-thinking firms that recognize the implications of their environmental impact can gain a competitive advantage. To this end, conservation strategies have shifted from obligation to opportunity, with the widespread adoption of greener practices and the reduction of carbon footprints. Innovative companies have recognized the external pressure and internal benefits of integrating sustainable processes into their operations. For instance, conservation of water and minimization of waste during the equipment's lifecycle has become an implicit aspect of business operations. More so, the use of energy-efficient machinery not only decreases operating costs but also significantly reduces the environmental burden. Additionally, we're witnessing an upsurge in automated waste management systems which streamline and optimize waste reduction. The rising adoption of renewable resources in equipment production also reflects on the shifting paradigm. Companies are progressively exploring and employing materials and components that have a lesser environmental impact, or can be sustainably sourced. This shift is a robust response to the escalating demand of environmentally conscious consumers and stringent regulatory policies. Furthermore, the manufacturing sector has observed the emergence of nanotechnology, which could profoundly impact food processing equipment. Potential nanotech applications, from boosting food safety to detecting contaminants, seem to hold the promise of revolutionizing the sector. Lynx-eyed entrepreneurs and seasoned investors are keeping a close eye on this budding field that could drive the next wave of industrial advancement. Navigating the future of the food processing equipment manufacturing industry entails being at the forefront of emerging technologies and trends. Observing these trends and adjusting business strategies is no longer a choice, but a survival tactic. From an entrepreneurial perspective, this calls for ongoing adaptation and innovation to meet market needs and drive growth. Among the dominant players in the food processing equipment manufacturing industry, GEA Group and Tetra Pak stand out with their commitment to sustainability and product innovation. GEA Group's comprehensive portfolio, automation capabilities, and Tetra Pak's innovative packaging solutions are testament to the success of adequately leveraging advancements. Similarly, Buhler AG's incorporation of nanotechnology hints towards the future, underlining the sector's shift towards enhanced safety and nutritional value in food processing. Rather than a few picking up the baton of sustainability and innovation, what our planet needs is a collective sprint towards a future where we balance economic prosperity and environmental protection. And for the business-savvy entrepreneur, this presents an ocean of opportunities – it's not just about doing what's right, but it's also good for business. Lastly, aligning with the global urgency for sustainability, the industry is innovating and adapting to develop solutions that are not only profitable but are also kind to the planet. This endeavour towards ecologically responsible manufacturing represents a significant shift in the way food processing equipment is created and highlights the sector's commitment to a sustainable future. In this rapidly evolving, highly competitive, and increasingly sustainable industry, the key players continue to exert their influence and introduce groundbreaking solutions. Their strategies, product lines, and market shares are instructive of the current market dynamics, acting as a barometer for the future trajectory of food processing equipment manufacturing. As our world rapidly evolves, so does the landscape of the food processing equipment manufacturing industry. This field, integral to maintaining and advancing global food supply chains, is shaped by emerging trends, shifting consumer demands, and innovation from leading industry players. On top of this, the infusion of transformative technologies such as Industry 4.0, Artificial Intelligence (AI), and the Internet of Things (IoT) continues to push the boundaries of production efficiency and product quality. However, navigating this complex industry is not without its challenges, such as adhering to rigorous quality standards and regulatory requirements. To help businesses make informed decisions, this discussion will delve into the landscape of food processing equipment manufacturers, addressing key dynamics, innovations, regulations, future projections, and tips for selecting a manufacturer. The food processing equipment manufacturing industry is a dynamic landscape constantly in flux, shaped by the evolving needs of consumers and the continuous drive for innovation. This rapid pace of development can be overwhelming, but if navigated well, it offers a tremendous range of opportunities. With a keen eye for what's trending, this article will delve into the current trends and demands shaping this industry. To begin with, automation is revolutionizing the food processing equipment manufacturing industry. Fueled by advancements in machine learning and robotics, this trend is not simply about replacing man with machine but optimizing processes for higher productivity, improved safety, and more consistent quality. Food manufacturers are increasingly embracing this trend, striving to achieve precision and efficiency that can only be derived from automated technology. At the same time, sustainability is unequivocally at the forefront of consumers' minds. Eco-conscious consumers are not only impacting the sourcing and packaging of food products but also the machinery involved in their production. Food processing equipment manufacturers are responding by designing equipment that consumes less energy, reduces waste, and uses eco-friendly materials. Sustainability is not merely a nice-to-have feature but a mandate shaping the future of this industry. Health and wellness are another growing trend influencing the industry. The demand for healthier, less processed food options is reshaping the type of equipment being made. Manufacturers are now producing machinery capable of handling raw and organic materials, infusing nutrients into products, and allowing for less invasive processes that keep food items as close to their natural state as possible. The consumer's quest for novelty is yet another driving force. With an influx of international cuisines, bold flavors, and novel food forms, the industry is consistently challenged to develop versatile and innovative machinery capable of producing these cutting-edge foods. The demand for machines that are capable of handling exotic ingredients, complex recipes, or unique food forms is growing. Lastly, traceability has also become vital in the food processing equipment manufacturing industry. As food safety concerns continue to attract regulatory attention worldwide, it's becoming essential for manufacturers to develop machinery equipped with integrated monitoring and reporting capabilities. These current trends shaping the food processing equipment manufacturing industry illustrate a complex ecosystem demanding the perfect blend of technology, sustainability, health consciousness, innovation and accountability. Staying ahead in such a rapidly transforming industry requires constant vigilance to evolving consumer preferences, emerging technologies, and regulatory changes. It is indeed an exciting time to be part of this industry, where change is the only constant, and innovation is the key to survival. The Emergence of Smart Technologies in Food Processing Equipment Manufacturing In an era of constant technological acceleration, the food processing equipment manufacturing industry is not left behind. Leveraging cutting-edge advances allows this sector to reshape its operations, bridging the gap between traditional practices and consumer demand for increased transparency, safety, and environmental consciousness. As businesses navigate the wave of technological change, it becomes increasingly crucial to focus on smart technologies, predictive maintenance, and advanced materials in design. Smart technologies or Industry 4.0, the latest industrial revolution, is redefining manufacturing processes. In the food processing equipment manufacturing sector, this is seen in the integration of the Internet of Things (IoT) and Artificial Intelligence (AI). IoT-enabled devices collect vast amounts of essential data from manufacturing processes, working together with AI to provide actionable insights. These insights can streamline production, reduce waste, optimize equipment performance, improve safety, and ultimately, enhance the bottom line. Similarly, Machine Learning (ML), a subset of AI, is making its mark by allowing equipment to self-improve. Over time, the system becomes more adept at detecting inefficiencies and implementing changes that boost overall performance. Ultimately, the incorporation of smart technologies fosters adaptive and responsive operations that are geared towards achieving operational excellence and fulfilling consumer expectations for food quality and safety. Predictive maintenance, another trend gaining traction, utilizes these subset technologies. By collecting and analyzing data, manufacturers can predict potential equipment breakdowns before they materialize, saving both time and money. Enabled by IoT sensors and advanced analytics, predictive maintenance empowers food processing equipment manufacturers to take a leap from reactive to preventive, substance-kindling substantial operational efficiency and significant cost reductions. Moreover, advanced materials and design are pivotal in synchronizing food equipment manufacturing with sustainability escalation and innovations. Harnessing novel materials that are durable, easy to sanitize, and environmentally friendly is vital in meeting stringent hygiene standards as well as sustainability targets. Furthermore, these radical materials can accommodate the increasing consumer penchant for novel and innovative food forms, adding another dimension of flexibility to the industry. The wave of technological advancements sweeping across industries presents lucrative opportunities for those who capitalize on it. For the food processing equipment manufacturing sector, the tide spices up operations with the promise of streamlined processes, improved product quality, predictive maintenance, advanced designs, and heightened efficiency. Consequently, staying abreast of technological trends becomes instrumental in creating a sustainable and competitive advantage. The road ahead, though propelled by technology, is steered by a thorough understanding and appreciation of consumer trends, emerging technologies, and changes in regulatory bodies. Businesses that customize their operations to the rhythms of these influences stand poised for success, prepared to steer the tide rather than just riding it. Success in the industry is a lot less about surviving the wave of change and more about mastering the art of navigating these waters. Regulatory standards in the industry present yet another challenge for manufacturers, but overcoming them can lead to substantial rewards. They pull the industry towards demonstrable safety, consistency, and accountability. These standards, whether they are health regulations, environmental concerns, or safety measures, are put into place to safeguard consumers. Upholding them is non-negotiable. Business-savvy manufacturers understand the impact of regulations and work proactively to not only meet them but exceed expectations as well. How is this achieved? Through a variety of measures, including investment in cutting-edge technology and a commitment to a culture of excellence. Bearing in mind the rise of Industry 4.0, manufacturers are increasingly leveraging technology enablers like Internet of Things (IoT), Artificial Intelligence (AI), and Machine Learning (ML) to ensure regulatory compliance. For instance, real-time data from IoT devices can be used to monitor production processes, ensuring that standards are met consistently and deviations are corrected promptly. AI and ML come into play by offering predictive analytics, which allows manufacturers to preemptively identify potential breaches in regulations and rectify them before inspection, thus improving overall compliance. Factoring in the trends of market reflexivity and consumer power, manufacturers are also catering to stricter and more specific demands. For example, the rising consumer interest in sustainable practices means that manufacturers must adhere to regulations surrounding sustainable sourcing and production, and innovate accordingly. This has led to the use of advanced materials with lower environmental impact in manufacturing equipment and mindful designing of products to minimize waste. Indeed, the face of equipment manufacturing is undergoing a significant transformation as manufacturers continue to refine processes to meet both regulatory standards and consumer demands. Embracing digital tools to simplify and streamline processes allows businesses to keep up with evolving demands, further enhancing product quality and efficiency. Even in the face of tough regulations, entrepreneurial manufacturers can succeed by understanding consumer preferences, emerging technology, and regulatory conditions. Finally, keep in mind that, regardless of the rapid changes in the broader business environment, knowledge sharing and effective communication within one's professional network remain crucial. Utilize all possible resources to ensure that your ambitious initiatives benefit from the wealth of perspective and experience that others in the industry can provide. In a world that never stops evolving, staying ahead requires clear vision, adaptable strategy, and a collective effort. In the ever-evolving landscape of the food processing equipment manufacturing industry, it is essential to understand where these tides of change are moving towards. Given the recurring themes of automation, sustainability, health and wellness, regulatory changes, and a seemingly insatiable demand for novel and innovative food experiences, one might wonder - what's up next? What are the imminent, significant shifts that businesses must prepare for, to remain competitive and relevant? Let’s delve into it. Interactivity and customization stand out prominently. With the proliferation of IoT, AI, and ML - it's no surprise that the equipment manufacturing industry will experience profound evolution too. Just as consumers are demanding unique food experiences, they’re also seeking personalization in the choices they make, whether it’s nutritional values, allergen-free options, or regional flavors. It heralds a future wherein equipment design won’t simply be about addressing functional requirements but also enabling adaptability for bespoke production runs. As consumers grow more concerned about the food they eat, transparency in food processing stands to gain even more importance. We’re looking at increased use of blockchain and other advanced technologies to ensure => full visibility from farm to supermarket shelf. This might also necessitate a shift towards designs enabling easy and efficient sanitation, to mitigate cross-contamination risks and an ever-growing list of pathogens. Another industry disruptor is the rapidly growing plant-based movement, necessitating equipment design adjustments or entirely new setups. Along with formulating plant-based alternatives posing a substantial challenge, processing these novel ingredients into finished products is an equally daunting task. Equipment manufacturers will need to pivot rapidly, testing and deploying innovative materials and construction designs to accommodate these new food processing requirements. Robotics, while not new, will see an increased adoption given the disparity between market demands and labor availability and cost. As robotic technology evolves, expect more agile and versatile systems, efficiently handling delicate operations without compromising speed or accuracy. Further on, to harmonize with the goals of UN’s 2030 Agenda for Sustainable Development, we anticipate a noticeable shift towards zero-waste, or minimal waste designs, including equipment enabling water, heat, and other by-product recovery measures. Besides environmental benefits, such practices also pose potential for improved operational efficiency and cost-effectiveness. Lastly, while data has been the buzzword for quite a while, its true value lies in insightful interpretation and strategic execution – elements that need to run deep in the food processing equipment manufacturing industry too. Equipment capable of measuring the likes of OEE (Overall Equipment Efficiency), and anomalies in key performance metrics, will pave the way to a smarter, more intuitive production floor. In conclusion, the future of the food processing equipment manufacturing industry appears to be inextricably linked with speedy adaptation to change, continual innovation, and a relentless drive towards efficiency and sustainability. One must remember, however, that such transformation isn't an option, rather an imperative in response to growing consumer consciousness and a highly dynamic global market environment. After all, it’s not just about keeping up, but perpetually staying a step ahead. Delving into the interactivity and customization in food processing equipment designs is key. As the market environment becomes progressively more competitive, businesses must anticipate needs and solve distinctive challenges. Tailored or modular systems that can be modified or expanded as per specific requirements are game-changers. They not only provide flexibility but also ensure that the production line maintains optimized performance, regardless of future changes in product demand, formulation, or type. Data transparency is another trending shift in the food processing industry. The term 'farm-to-fork' is no longer a marketing trick but a necessity for businesses. Blockchain technology, which ensures absolute data transparency, can be integrated into the manufacturing equipment. It provides clear visibility within the supply chain, ensuring food safety, and instills trust amongst end consumers. The rise of the plant-based movement also influences equipment design and processing requirements. With the increasing demand for plant-based proteins, choosing equipment that can efficiently process raw materials like legumes, grains, or biomass is essential. The equipment should be designed to maintain the nutritional and sensory aspects of the product. Labor availability and skyrocketing costs have initiated the surge in adoption of robotics. Robotic solutions can perform monotonous tasks efficiently, reducing the dependency on labor while improving accuracy and productivity. Robots can be programmed for different tasks, like sorting, packaging, and inspecting, offering exceptional reliability. In the era of social responsibility, shifting towards zero-waste or minimal waste designs gains importance. Businesses must choose manufacturers who follow a circular economy approach. These manufacturers focus on reducing waste production, reusing, and recycling, thus pushing the boundaries of sustainability in the food processing equipment industry. Finally, the role of data analysis and interpretation in improving efficiency and performance metrics in equipment manufacturing cannot be overstated. Advanced analytics can help streamline manufacturing processes and mitigate risks. Data science can support businesses in generating insights from the vast amounts of data created, uncovering opportunities for improvements, and uncovering potential problems before they become severe issues. In essence, in the dynamic world of food processing, businesses need to be astute, sagacious, and readily adaptable. Selecting the right food processing equipment manufacturer is a crucial decision that can significantly impact the business's profitability and reputation. With the considerations listed above, businesses have the know-how to make the most optimal choice. Upon thorough examination of the food processing equipment manufacturing industry, we can deduce that the rapid pace of technological innovation and shifting market trends significantly contribute to the industry's future. The role of AI, the IoT, and Industry 4.0 cannot be over-emphasized in this equation, as these elements present a myriad of opportunities for increased efficiency and overall industry growth. Furthermore, meeting ever-evolving quality standards and regulations remains a crucial aspect for manufacturers in this field. For businesses seeking suitable manufacturers, a careful evaluation focused on factors such as technological adaptation, reliability, customer service, and product quality should be paramount. As we press on into an increasingly interconnected world, it is with fervent anticipation we watch how these dynamics will further shape the future of food processing equipment manufacturing and our global food supply chain.Food processing equipment manufacturers

Emerging Technologies in Food Processing

Global Market Trends and Forecasts | Food processing equipment manufacturers

Key Players and Competitive Landscape

Sustainability and Environmental Impact | Food processing equipment manufacturers

Understanding the Market | Food processing equipment

Technological Innovations

Quality Standards & Regulations

Future Projections

Selecting a Manufacturer | Food processing equipment